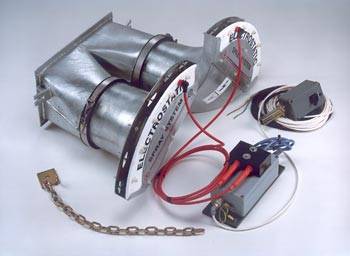

"MARTIGNANI - KWH" ELECTROSTATIC DEVICE

|

The FIRST to be produced in EUROPE (1981) and the ONLY ONE tried and tested in ITALY and ABROAD with phytotherapeutic results.

Already established in farming practice with thousands of vine and fruit-growers throughout the world, this device represents one of the most important contributions towards progress in research into new solutions able to optimize application techniques. Numerous tests have shown that it can REDUCE LOSSES THROUGH DRIFTING by 85%. On request, it can be applied to the entire "MARTIGNANI-KWH" range with the sole exception of the "BORA HYD-ROBOT" series.

|

TECHNICAL PRINCIPLE

Thanks to the electrostatic fields formed between the plants, which are good conductors (sap, mineral salts, moisture, etc.) and the chemical mist sprayed from K.W.H. blowers with their special electrostatic charge, droplets saturated with active principle are attracted by the vegetation (branches, leaves, etc.).

This reduces losses through drifting even in windy weather.

Years of research and practical experiments already conducted to date in this particular field by eminent institutes in North America (California), South America (Argentina- Uruguay), Asia (Philippines), Africa (Tunisia) and Europe (Holland, France, Germany, Hungary, Italy) have given surprising results. All this has allowed researchers to affirm that electrostatic mist-blowing sensibly improves the many advantages acknowledged by everyone when it comes to low-volume plant-protection treatments while eliminating those few aspects that certain people still question once and for all.

|

ADVANTAGES

- The plant protection products are evenly distributed and adhere perfectly to even the undersides of the leaves.

- Less loss thru' drifting.

- Total use of the pesticide, thus even less product required per hectare.

- Total coverage of even the tallest parts of the trees (where conventional mist-blowers are unable to reach) since the chemical mist that forms above the plants is attracted by these latter.

- Jobs are done faster (up to 12 Km/hour).

- More time saved.

- Healthier plants and better quality produce.

- A notable reduction in environmental pollution.

- The risk of the operator being contaminated by pesticides (both by inhalation and by contact) is reduced by 70%.

Media and Video Demonstrations

Shepparton News Editorial September 2012

Electrostatic Mist Blowers at Frutas Esther in Spain

Electrostatic Mist Blowers VS Air Blast Sprayers: The Differences

Electrostatic Martignani 3 Row Unit Demo

Electrostatic Martignani 3 Row Unit Demo 2

Electrostatic Martignani Cognac 2 Row Unit Demo